Design and Implementation of River Cleaning Boat

Ieee account.

- Change Username/Password

- Update Address

Purchase Details

- Payment Options

- Order History

- View Purchased Documents

Profile Information

- Communications Preferences

- Profession and Education

- Technical Interests

- US & Canada: +1 800 678 4333

- Worldwide: +1 732 981 0060

- Contact & Support

- About IEEE Xplore

- Accessibility

- Terms of Use

- Nondiscrimination Policy

- Privacy & Opting Out of Cookies

A not-for-profit organization, IEEE is the world's largest technical professional organization dedicated to advancing technology for the benefit of humanity. © Copyright 2024 IEEE - All rights reserved. Use of this web site signifies your agreement to the terms and conditions.

Accessibility Links

- Skip to content

- Skip to search IOPscience

- Skip to Journals list

- Accessibility help

- Accessibility Help

Click here to close this panel.

Purpose-led Publishing is a coalition of three not-for-profit publishers in the field of physical sciences: AIP Publishing, the American Physical Society and IOP Publishing.

Together, as publishers that will always put purpose above profit, we have defined a set of industry standards that underpin high-quality, ethical scholarly communications.

We are proudly declaring that science is our only shareholder.

IoT Based Water Surface Cleaning and Quality Checking Boat

B. Saran Raj 1 , L. Murali 1 , B. Vijayaparamesh 1 , J. Sharan Kumar 1 and P. Pragadeesh 1

Published under licence by IOP Publishing Ltd Journal of Physics: Conference Series , Volume 1937 , International Conference on Novel Approaches and Developments in Biomedical Engineering-2021 (ICNADBE 2021) 22-23 April 2021, Coimbatore, India Citation B. Saran Raj et al 2021 J. Phys.: Conf. Ser. 1937 012023 DOI 10.1088/1742-6596/1937/1/012023

Article metrics

270 Total downloads

Share this article

Author e-mails.

Author affiliations

1 P. A. College of Engineering and Technology, Pollachi-642002, Tamil Nadu, India

Buy this article in print

It is foremost important to keep the water bodies around us to be clean. It is very terrible that huge amount of garbage is deposited on water bodies every year. Monitoring the quality of water that is present in the water bodies is also very important in today's world. There is a group of people who keep on monitoring the changes that occurs on the surroundings who are named as Catchment Management Authorities. Catchment Management Authorities monitor and provide real-time day to day updates on environmental protection and tracking pollution sources. A cheap non-wired aquatic monitoring system will enable cost effective water quality measurement by collecting data as well as assisting catchment managers to maintain the health of aquatic ecosystem. The work deals with finding a way for the uncertain effects of the floating particles, hence reducing the harmfulness created on behalf of the floating particles that incorporates floating materials and curbs. Our work aims to create a garbage gathering object to monitor the lakes and ponds and also measure the condition of water by measuring several parameters. In addition, it helps to understand the water pollution using data analysis. The main feature of this project is to collect of floating objects from the surface of the water into a trash container. The Secondary work of our project is to measure the water quality by using sensors, by measuring the water quality parameters we can be able to predict the unfavourable conditions of water living creatures. pH Sensor and Turbidity Sensor are used in our project to measure the acidity and basicity of the water and turbidity level of the water respectively. The main motto is to clean the surface of the water and check the quality of the water which helps for aquatic ecosystem.

Export citation and abstract BibTeX RIS

Content from this work may be used under the terms of the Creative Commons Attribution 3.0 licence . Any further distribution of this work must maintain attribution to the author(s) and the title of the work, journal citation and DOI.

Review of Underwater Ship Hull Cleaning Technologies

- Research Article

- Open access

- Published: 13 October 2020

- Volume 19 , pages 415–429, ( 2020 )

Cite this article

You have full access to this open access article

- Changhui Song 1 &

- Weicheng Cui 1 , 2

36k Accesses

74 Citations

Explore all metrics

This paper presents a comprehensive review and analysis of ship hull cleaning technologies. Various cleaning methods and devices applied to dry-dock cleaning and underwater cleaning are introduced in detail, including rotary brushes, high-pressure and cavitation water jet technology, ultrasonic technology, and laser cleaning technology. The application of underwater robot technology in ship cleaning not only frees divers from engaging in heavy work but also creates safe and efficient industrial products. Damage to the underlying coating of the ship caused by the underwater cleaning operation can be minimized by optimizing the working process of the underwater cleaning robot. With regard to the adhesion technology mainly used in underwater robots, an overview of recent developments in permanent magnet and electromagnetic adhesion, negative pressure force adhesion, thrust force adhesion, and biologically inspired adhesion is provided. Through the analysis and comparison of current underwater robot products, this paper predicts that major changes in the application of artificial intelligence and multirobot cooperation, as well as optimization and combination of various technologies in underwater cleaning robots, could be expected to further lead to breakthroughs in developing next-generation robots for underwater cleaning.

Similar content being viewed by others

Unmanned aerial vehicles (UAVs): practical aspects, applications, open challenges, security issues, and future trends

Syed Agha Hassnain Mohsan, Nawaf Qasem Hamood Othman, … Muhammad Asghar Khan

Recent Advances in Unmanned Aerial Vehicles: A Review

Faiyaz Ahmed, J. C. Mohanta, … Pankaj Singh Yadav

Robotics cyber security: vulnerabilities, attacks, countermeasures, and recommendations

Jean-Paul A. Yaacoub, Hassan N. Noura, … Ali Chehab

Avoid common mistakes on your manuscript.

1 Introduction

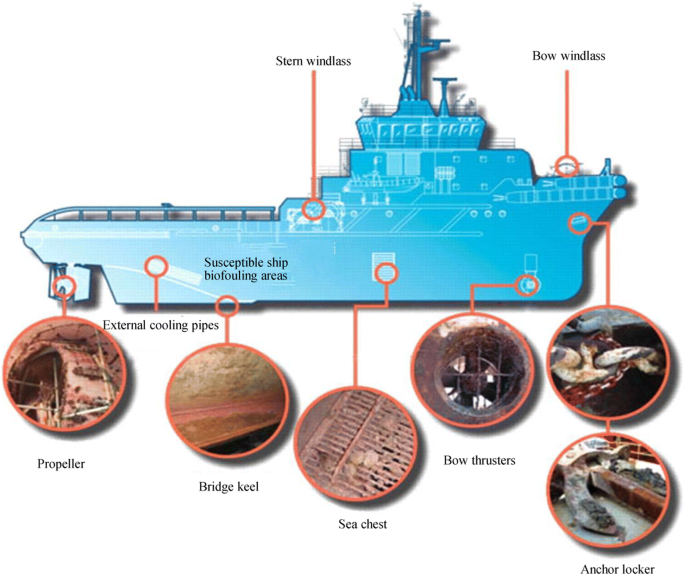

Vessels or structures that partially reside below the surface of seawater or freshwater are subjected to various levels of fouling by marine (saltwater) or aquatic (fresh water from lakes and rivers) organisms, respectively (Cioanta and McGhin 2017 ). At the base of the fouling mechanism for vessels and structures residing in sea or freshwater are biofilms formed on such structures, which constitute the glue between marine or aquatic organisms and the actual structure (Hua et al. 2018 ). The biofilms form and the fouling organisms attach to all subsurface structures, such as propellers, rudders, inlet and outlet ports, sonar housings, and protective grills, as shown in Figure 1 . The more diverse or intricate a structure is, the more difficult and costly it is to remove the biofilms and the organisms. Hull and propeller performance may deteriorate over time because of biofouling and mechanical damage; thus, poor hull conditions may decrease the energy efficiency. Moreover, biofilms on the hull can affect the ship’s dynamics by increasing drag and the required propulsion. If the ship is idle for a long time or has little activity (for example, staying at the port), then the growth of marine biofouling on the hull will be accelerated (Tribou and Swain 2010 ; Adland et al. 2018 ).

Marine fouling organisms attach to all subsurface structures of the typical ship (Bixler and Bhushan 2012 )

Hull fouling on the vessels is a major problem that leads to higher fuel consumption and consequently increased air pollution (Tribou and Swain 2010 ; Cioanta and McGhin 2017 ; Hua et al. 2018 ). Frictional resistance due to buildup of biofilms, sea grass, barnacles, and other marine creatures on the hull as a vessel goes through water will increase its fuel consumption. For example, a 30% increase in resistance caused by the moderate biological contamination of a 100 000–DWT tanker hull will increase the ship’s fuel consumption by up to 12 tons/day, which is the reason for the increase in ship operating costs and emissions (Smith and Colvin 2014 ). Hull fouling on the vessels can also cause the spread of alien species that rapidly multiply in local waters without natural enemies (Bax et al. 2003 ; Godwin 2003 ; Drake and Lodge 2007 ).

Typically, most vessels perform a coating update per 3 to 5 years (Hua et al. 2018 ). Moreover, in the U.S. Navy, propeller cleaning work is recommended to be conducted six times per year, while hull cleaning is to be carried out three times per year (Cioanta and McGhin 2017 ). Various methods are currently being used to rid vessel hulls of biofouling through cleaning and to monitor the structural integrity of the hull (Smith and Colvin 2014 ). In summary, the most common methods used for biofouling removal are dry-docking cleaning, antifouling paint, and periodic underwater cleaning (Morrisey and Woods 2015 ). Chambers et al. ( 2006 ) pointed out that a good method of removing biofouling is the use of high-pressure abrasives in dry docks. In the dry-dock cleaning method, ship owners accept the increased sailing cost and wait to have a complete hull cleaning and repainting in the dock. The method requires the ship to enter the dock and leave the water entirely, and then clean the surface of the ship through high-intensity manpower. Dry-dock cleaning has the shortcomings of long operation cycles, high labor intensity, and high cleaning costs. In the antifouling paint method, the ship hulls are sprayed with soft antifouling paint, which can effectively kill or slow the growth of organisms by gradually releasing biocides. The antifouling effect is greatly reduced as the paint ages. Therefore, the antifouling paint needs to be reapplied. However, many jurisdictions have considered dockside cleaning illegal because the hazardous substances of antifouling paint particles that may spread into contaminate the water during cleaning (Smith and Colvin 2014 ). In the periodic underwater cleaning method, the use of hard coatings that can last for at least 10 years and may even extend the life of the hull is recommended. In the long run, hard coatings that can be cleaned underwater are an optimal solution and are neutral to the ocean because the waste generated by cleaning does not contaminate the marine environment (Morrisey and Woods 2015 ).

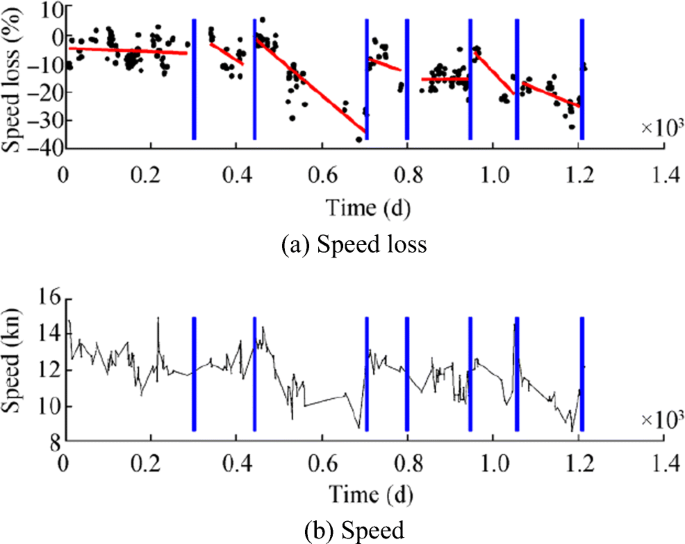

Oliveira ( 2017 ) proposed tools for improving current practices related to hull performance management, with a focus on the adhesion strength of marine organisms on different coatings and estimates of hull fouling. The author uses the raw data provided by the shipping company, spanning a period of over 3 years, to draw the percentage speed loss and vessel speed of the vessel, as shown in Figure 2 . Adland et al. ( 2018 ) suggested a new method to assess the results of periodic hull cleaning operations on energy efficiency by comparing fuel consumption in the interval after the ship cleaning. Hull cleaning can play a key role in improving fuel efficiency, thereby reducing sailing costs and emissions.

Speed loss and measured speed through water for a tanker over a period of 3 years. Hull and propeller cleaning events are marked with vertical blue lines (Oliveira 2017 )

The main purpose of this review is to study the advantages and shortcomings of in-water hull cleaning technologies on the basis of our understanding of current and emerging cleaning technologies in the references. This review can be used to guide the design of efficient cleaning tools or to develop environmentally friendly robotic systems for hull cleaning. The rest of this paper is organized as follows: Section 2 presents the main devices and methods that are widely used in underwater hull cleaning. Section 3 reviews the techniques of underwater vehicles used for hull cleaning. Section 4 discusses current challenges, perspectives, and future work toward improved underwater hull cleaning technologies. Section 5 outlines the main conclusions.

2 Cleaning Devices and Methods

The initial cleaning work is performed by workers to remove biofouling by hand. Floerl et al. ( 2010 ) presented that manual scrubbing or wiping is widely used in cleaning recreational boats.

With the development progress, various new cleaning tools have been manufactured to increase the efficiency of cleaning operations and greatly reduce the labor intensity of cleaning operations. Cleaning methods and tools can be divided into three categories:

Manual hull cleaning

Powered rotary brush cleaning systems

Noncontact cleaning technology

2.1 Manual Hull Cleaning

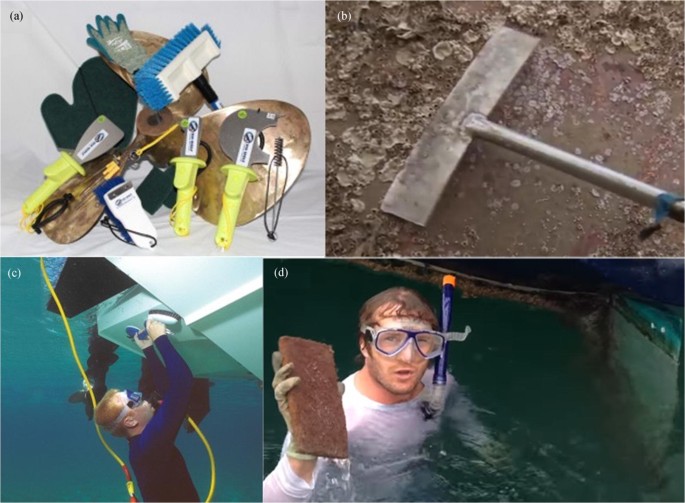

Manual cleaning of biofouling surfaces is commonly performed on small ships, e.g., recreational yachts and small fishing boats. In accordance with the amount and characteristic of the biofouling (e.g., slime, biofilm, sea grass, and encrusting organisms) and on the type of antifouling coating applied, cloths, brushes, or scraping devices are used to remove biofouling organisms, as shown in Figure 3 .

Manual hull cleaning tools and methods. a The cleaning tools provided by Top Shelf Marine Company (image: www.topshelfmarine.com/hull-and-bottom-cleaning ). b A shovel for removing barnacles (video screenshot: tv.cntv.cn/video/C10595/1a24d1bb3c7e453d8fa9183e8d62de44 ). c A diver using a handheld brush to clean the bottom hull (image: Citimarine Store , https://citimarinestore.com/citiguide/hookah-dive-systems-perfect-for-cleaning-hull-underwater/ ). d A snorkeler using a cleaning sponge to remove biofouling organisms (video screenshot: www.youtube.com/watch?v=0biZ4ysKHM0 )

When a snorkeler or diver performs manual cleaning, removing all the marine creatures on the hull is impossible. A survey on the degree of residual biofouling on the rudder, propeller, stern tube, and struts of the vessel was performed before and after manual cleaning. A professional diver dispatched by the cleaning company scrubbed the biofouling by using a handheld brush, but about 40% of the species remain in the area under investigation even after the cleaning operation (Davidson et al. 2008 ).

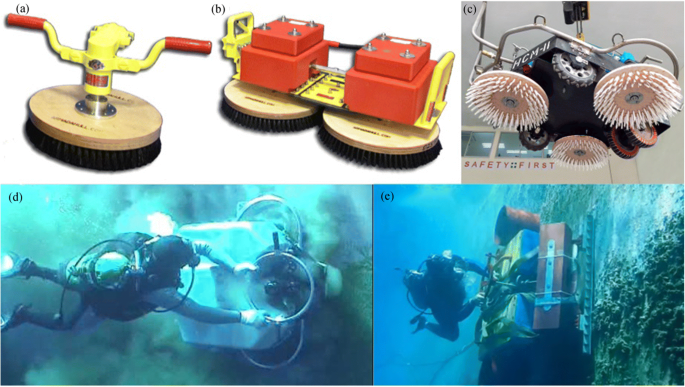

2.2 Powered Rotary Brush Cleaning Systems

Underwater cleaning methods have gradually evolved from manual operation to mechatronics equipment, especially for large vessels. Handheld cleaners, large cleaning equipment, and cleaning robot systems have been developed. Large brush devices can usually be used when quickly cleaning flat or slightly curved areas of the hull, and small brushes can be used for better results when cleaning the propeller (Davidson et al. 2008 ; Hopkins et al. 2009 ). A single brush, double brushes, or multiple brushes that are powered by hydraulic motors could be installed in large rotary brush devices, as shown in Figure 4 .

Powered rotary brush. a , b A device manufactured by Armada Systems, Inc. (image: https://armadahull.com/products/ ). c A device manufactured by Divetech Marine Services Pte Ltd. (image: http://www.divetechmarine.com/page/equipment.html ). d , e Divers using a rotary brush to clean biofouling (video screenshot: https://www.youtube.com/watch?v=NRQsPoHD9Jw ; https://www.youtube.com/watch?v=G7d1bbAU7RA&feature=youtu.be )

2.2.1 Unpowered Cleaning Brush

Brushes are used all the time to remove deposits from the surface of ships. Generally, different types of brushes are used based on the type of biofouling to be removed and the paint of the vessels. Nylon brushes can be used when cleaning a certain thickness of mud and sea grass on the hull, and steel brushes can be used when cleaning barnacles, heavy grass, and zebra mussels. A suitable cleaning brush needs to be selected according to the construction material of the hull. For example, nylon or nonmetallic brushes are used on ships constructed of fiberglass, wood, aluminum, and steel, while metal brushes are used on ships constructed of aluminum or steel. Many companies have been working on underwater hull cleaning devices that are widely used, including Armada Systems, Inc. ( www.armadahull.com ), Subsea Industries ( www.subind.net ), and Phosmarine Brush Kartetc ( www.brush-kart.com ). Taking Armada Systems, Inc., as an example, we surveyed its typical rotating brush products, as shown in Figure 5 and Table 1 .

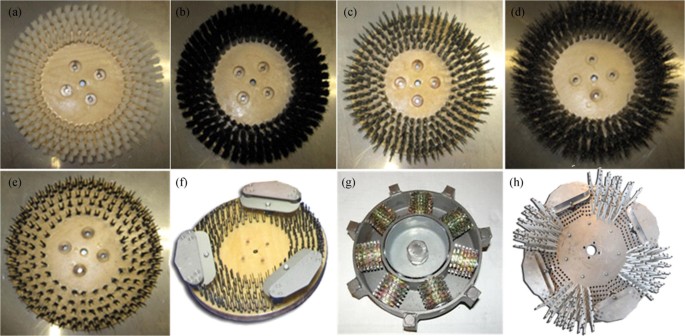

Brushes manufactured by Armada Systems, Inc.: a nylon brush; b polypropylene brush; c grit brush; d stainless steel row brush; e flat wire steel brush; f flat wire with cutouts and blades; g barnacle cutter; h rebuildable heavy barnacle brush

2.2.2 Powered Rotating Devices

Handheld powered rotating brush devices can be divided into single-brush head, double-brush head, and multiple-brush head, as shown in Figure 4 . The powered rotating device generates the adsorption force when rotating the brush units, which makes it attracted to the hull. The diver can adjust the cleaning direction of the device and the rotation speed of the brush according to the cleaning area (Albitar et al. 2016 ). In addition to hydraulic brushes, electric powered devices are used in underwater robots. Companies such as Armada Systems, Inc., and Subsea Industry that focus on the development of marine cleaning equipment have manufactured many powered rotating devices that use different brushes to remove marine organisms attached to the submerged hull to accommodate different hulls and coatings.

2.3 Contactless Underwater Cleaning Method

The cleaning or grooming of a marine or aquatic vessel or structure, such as vessels and oil platforms, generally involves methods that use brushes, scrapers, and other abrasive means to clean (Cioanta and McGhin 2017 ). These methods can be damaging to the welds, rivets, and protrusions of the water vessels or underwater structures, thereby compromising their mechanical integrity. Present cleaning or grooming methods fall short of being thorough, leaving behind biofilms, which represent the substrate and contain the nutrients that different marine organisms use for growth and anchor (Cioanta and McGhin 2017 ). In this section, we mainly survey contactless cleaning methods and apparatuses, including the high-pressure water jet method, the cavitation water jet method, and the ultrasonic cleaning method. When these cleaning techniques are used to remove the biofouling from the hull, the damage to the coating can be better reduced compared with rotating brushes (Morrisey and Woods 2015 ).

2.3.1 High-pressure Water Cleaning Jets

The high-pressure water cleaning method relies on its own impact force to remove biofouling on the hull. A high working pressure corresponds to a good cleaning effect (Albitar et al. 2016 ). Some researchers have used high-pressure water technology in underwater hull cleaning (Osaka and Norita 2014 ; Smith and Colvin 2014 ; Chen et al. 2017 ; Hua et al. 2018 ; Yan et al. 2019 ).

If the appropriate water pressure is used to safely remove the slime layer, then the effect on the hull coating is minimal (Floerl et al. 2010 ).

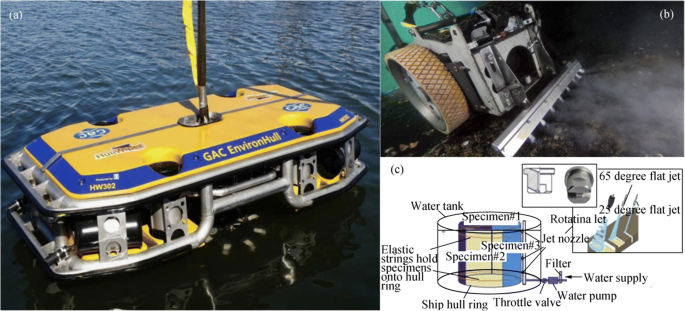

The HullWiper (HullWiper, https://www.hullwiper.co/ ), shown in Figure 6a , cleans the hull and simultaneously collects biofouling removed from the ship rather than directly discharging them into the water; the latter causes the risk of species spreading. HullWiper takes local water as a medium for hull cleaning and sprays high-pressure water up to 50–450 bar on the hull, cleaning up to 1500 m 2 /h, to remove biofouling. The Magnetic Hull Crawler (Cybernetix, www.cybernetix.fr ) vehicle, shown in Figure 6b , is a remotely operated system dedicated to inspection, cleaning, and maintenance of ships, offshore floating units, and offshore oil and gas industries, and it has been used for more than 10 years. The Magnetic Hull Crawler uses high-pressure jets up to 1000 bar, with different jet openings and attack angles available. The underwater cleaning width of the system is 500 mm, and the cleaning efficiency can reach 100–200 m 2 /h. Hua et al. ( 2018 ) designed an en-route operated hydroblasting system by using high-pressure water cleaning jet for counteracting biofouling on-ship hulls. The experimental system is shown in Figure 6c .

High-pressure water cleaning jet technology. a HullWiper (image: HullWiper, https://www.hullwiper.co/ ). b Magnetic Hull Crawler (image: Cybernetix, www.cybernetix.fr ). c Illustration of biofouling cleaning system (Hua et al. 2018 )

2.3.2 Cavitating Water Cleaning Jets

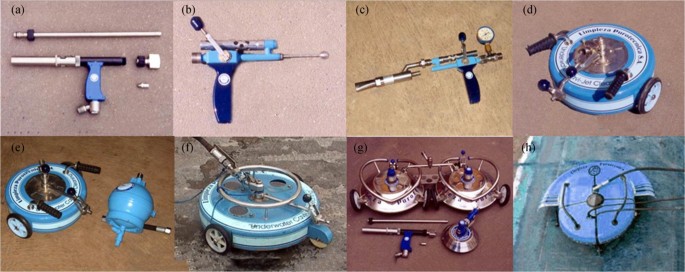

Cavitating water jet technology is an improved version of high-pressure water cleaning technology that uses specially designed nozzles, which convert high-pressure water into cavitation water (Kalumuck et al. 1997 ; Balashov et al. 2011 ; Pivovarov 2009 ; Floerl et al. 2010 ; Zabin et al. 2017 ). The cavitation jet introduces cavitation into the high-pressure clean water, which is highly aggressive and enhances the cleaning of the hull. The number of bubbles in the cavitation water can be increased by improving the nozzle design. The bubbles rupture as they approach the hull, resulting in very high local stresses, which can result in greater cleaning power. This feature is a significant advantage of conventional high-pressure water jets operating at the same pump pressure. Many companies have developed jet nozzles and cleaning devices/systems based on cavitation water jet technology to enable underwater cleaning efficiency. Taking Cavi-Jet International as an example, we surveyed its typical cavitating water jet products, as shown in Figure 7 .

Jet nozzles and cleaning devices manufactured by Cavi-Jet International. a Multisprayer Cavi-Jet pistols. b Single-sprayer Cavi-Jet pistols. c Water-and-sandblasting Cavi-Jet pistols. d Small Cavi-Jet heads. e Cavi-Jet dampers. f Large Cavi-Jet heads. g Twin Cavi-Jet heads. h Cavi-Jet robots (image: http://www.cavi-jet.com/ )

Cavi-Jet International offers a variety of hull cleaning systems, from handheld equipment to diver-operated vehicles. The Cavi-Jet pistols shown in Figure 7a to c are used by divers to clean complex surfaces of different shapes and areas that are difficult for large cleaning equipment to reach. The water-and-sandblasting Cavi-Jet pistol is specially designed to remove hard marine fouling on the hull. These Cavi-Jet pistols can treat up to 50–100 m 2 of hard algae, shellfish, and shell fouling or 100–250-m 2 soft barnacle and shell fouling per hour, with 25–35 MPa pump power. The Cavi-Jet nozzles, shown in Figure 7d–g , are used to clean the flat and slightly curved surface of the vessel and are equipped with a suction system for adhering to the hull being cleaned. The Cavi-Jet Robots, shown in Figure 7h , could be remotely operated to clean slightly curvilinear hull surfaces at a high speed.

2.3.3 Ultrasonic Cleaning Technology

Over the past decades, ultrasonic cleaning technology has been used in many cleaning applications, e.g., medical equipment, jewelry, vessels, and marine structures (Caduff 1990 ; Mazue et al. 2011 ; Erneland 2014 ; Legg et al. 2015 ; Albitar et al. 2016 ; Yan et al. 2019 ). The application of ultrasonic cleaning technology to underwater ship cleaning has become possible due to the rapid development of digital electronics and transducer technology over the past two decades. The method relies on simultaneously generating ultrasound energy pulses over a plurality of frequency ranges. This energy produces a pattern of alternating positive and negative pressures. This alternating pattern then produces tiny bubbles during negative pressure and implodes the bubbles during positive pressure. The destructive energy of the implosion not only provides a cleaning effect on the hull but could also eliminate the marine creatures removed from the hull to some extent (Aldrich and Qi 2005 ).

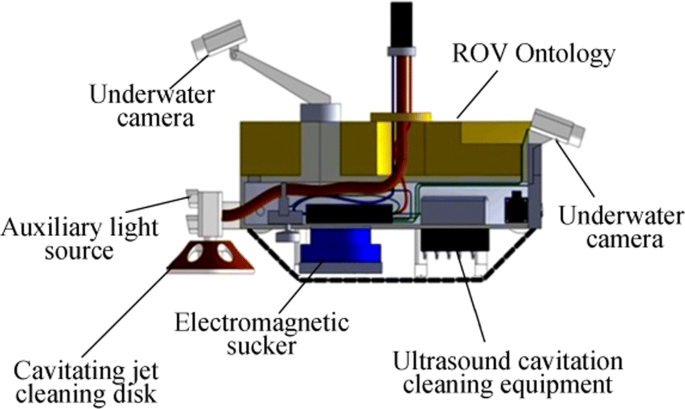

Mazue et al. ( 2011 ) designed a cleaning system that consists of three transducers operating at low frequency and a suction device, and they tested the system on a 15-m boat. Cioanta and McGhin ( 2017 ) proposed a cleaning apparatus for a ship’s hull and underwater structures. This apparatus employs acoustic pressure shock waves that can provide high compressive pressures (in excess of 100 MPa) followed by large and long-lasting tensile/negative pressures (in excess of 10 MPa), which can generate large cavitational bubbles during their collapse and very powerful water jets with speeds in excess of 100 m/s. These two synergetic phase effects of the acoustic pressure shock waves can work in tandem to clean a ship’s hull or any underwater structures subject to marine or aquatic biofilm formation and subsequently to marine or aquatic fouling. Courson and Shelburne ( 2001 ) proposed a portable diver-operated device for cleaning underwater surfaces, which includes an ultrasonic energy source in the housing with a compliant portion around the opening that can be engaged around the fouled hull. Yan et al. ( 2019 ) designed an underwater cleaning robot that uses the cavitation cleaning technology, as shown in Figure 8 .

Ultrasonic underwater cleaning applications (Yan et al. 2019 )

2.3.4 Laser Cleaning Technology

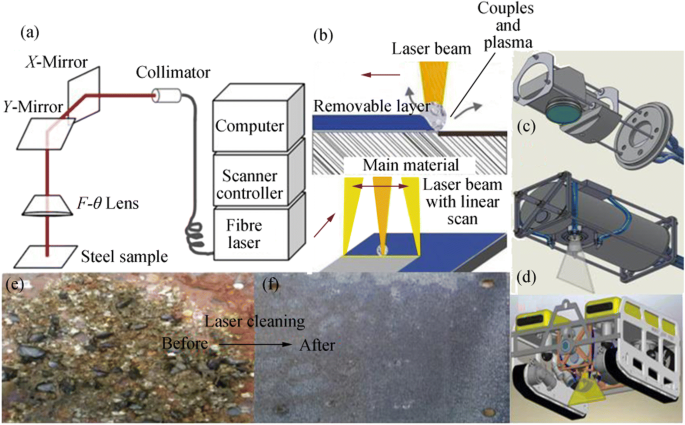

Laser technology and its application technology have made great progress in the past 30 years. Laser cleaning technology, which uses the laser radiation scanning the treated hull, has the advantages of faster surface cleaning capability, precise selective processing capability, and better cleaning process control through feedback over rotary brush and high-pressure water cleaning (Fowler 1987 ; Veiko and Shakhno 2002 ; Song et al. 2004 ; Chen et al. 2010 ; Kostenko et al. 2019 ). Laser blasting or cleaning, as shown in Figure 9b , could be introduced commercially in many industrial fields, including underwater ship cleaning.

Laser cleaning technology and devices. a Illustration of the laser surface preparation system (Chen et al. 2012 ). b Technical implementation of laser cleaning. c Laser scanning device. d The designed ROV. e , f Results of underwater laser cleaning (Kostenko et al. 2019 )

Fowler ( 1987 ) designed a laser cleaning system to remove marine creatures from the hull efficiently. This optical cleaning system comprises a high-energy strobe lamp that has a capacity of 10 kJ, which connects to the capacitor used to store electrical energy. A power system is used to charge the capacitor. This high-power capacitor is used to charge the strobe lamp, which produces high-power laser beams to scan the treated surface. Chen et al. ( 2012 ) developed a cleaning technique for the surface preparation of steel by using a 500-W pulsed high-power fiber laser, as shown in Figure 9a . Kostenko et al. ( 2019 ) developed a new underwater cleaning system that consists of an underwater robot and laser cleaning equipment that can be used to clean the hull, as shown in Figure 9d . However, the details of the design of the cleaning laser are not given in the paper.

2.3.5 Other Cleaning Technologies

Heating is widely used to kill most creatures, including marine organisms. Heating methods are widely used to eliminate marine organisms in power station cooling systems and marine creatures entering the vessel’s ballast tanks (Wotton et al. 2004 ; Balashov et al. 2011 ; Floerl et al. 2010 ). The heating method has a good effect on killing marine organisms when the vessel has light and moderate biofouling (Albitar et al. 2016 ). Ultraviolet radiation technology is increasingly used for water sterilization and can be used to kill marine creatures at the early growing stage at which they attach to the hull (Lakretz et al. 2009 ; Satpathy et al. 2010 ). Envelope technology can effectively kill all biofouling on the hull. By completely wrapping the vessel for a period, this method deprives organisms of the resources they need to survive, such as oxygen, temperature, and food (Floerl et al. 2010 ; Albitar et al. 2016 ).

3 Adhesion Technologies in Underwater Cleaning Robots

Most of the above-mentioned cleaning devices could be used by handheld cleaners, semiautomatic cleaning equipment, and cleaning robot systems. When divers clean the vessel in the water, there are disadvantages, such as high labor intensity, low efficiency, limited working time, and potential personal injury. Therefore, underwater hull cleaning robots have become the best solution to replace divers for hull cleaning (Yuan et al. 2004 ; Lee et al. 2012 ). To meet the requirements of underwater ship cleaning, the robot needs to walk close enough to the hull without damaging it. The robot requires six degrees of freedom (DOF) of motion and centimeter position accuracy (Lee et al. 2012 ). The most important functional requirement of the underwater cleaning robot is to maintain continuous adsorption capacity because of the steep and irregular surface of the ship, as well as the influence of the current, wave, and wind.

3.1 Magnetic Adhesion

Magnetic force is widely used in underwater cleaning systems to hold the robot onto the ship in the vertical or overhanging hull. The adhesion principle is to use the mutual attraction between the magnet and the ferromagnetic material, such as the ship hull and marine structure, to apply direct pressure between the robot and the ship surface. Therefore, enough magnetic force and friction force must be ensured to balance the external forces that are applied to the robot. At present, the widely used adsorption methods mainly include permanent-magnetic and electromagnetic adsorption; and the mechanical structure forms are the crawler and wheel type.

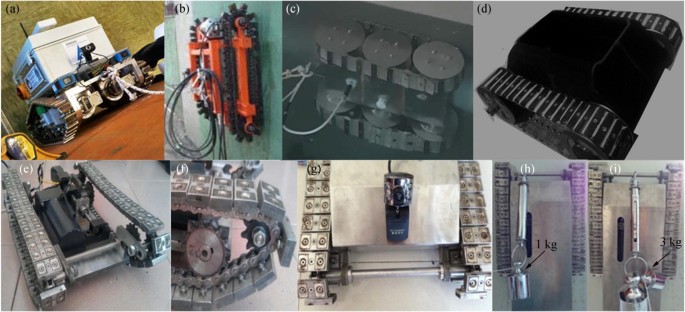

3.1.1 Permanent-Magnetic Adhesion Technology

With the emergence of new permanent magnet materials, very strong magnetic forces can be generated by using permanent magnets with very small size and mass. Therefore, permanent magnets have been integrated into wheel or track designs and widely used in climbing robots and underwater cleaning robots, as shown in Figure 10 .

Robots using permanent magnets. a MARC final release, during vertical climbing test (Vodenicharov et al. 2017 ). b WCRSRR robot (Yi et al. 2009 ). c First-generation ARMUS robot inspecting ship’s hull under the water line. d Second-generation ARMUS robot (Vodenicharov et al. 2017 ). e – g Ship inspection robot. h , i Payload capacity test (Huang et al. 2017 )

Based on the first two versions, the M2000 robot has been designed to improve agility and overall productivity. The robot uses permanent magnets to attach to the ship, and it uses high-pressure water jets to remove corrosion from the hull and recycle water and waste. The M2000 robot can be operated in narrow areas and around obstacles, and it can traverse obstacles on the hull and drive at a speed of about 0.6 m/s (Ross et al. 2003 ). Yi et al. ( 2009 ) designed a wall-climbing robot called WCRSRR to remove rust from the ship hull. This robot uses ultra-high-pressure water jets as a cleaning device, as shown in Figure 10b . The main parameters of the robot are as follows: weight is about 90 kg, the size is about 735 mm × 752 mm × 280 mm, the forward speed is 0.05 m/s, and the cleaning width is 250 mm. The first-generation ARMUS robot is a three-axis tracked system that attaches to the hull with the help of neodymium magnets. The attraction force that the robot tracks provide to the surface is 336 kg, which is enough to keep the robot clamped to the hull surface even when the ship is in motion. The second-generation ARMUS robot is designed in a way that it can remain underwater for an unlimited amount of time and work on both sides (external and internal like cargo holders) of the ship’s hull. The advantage of the permanent magnet adsorption method is that the magnetic force maintenance does not require external energy maintenance, which means that the adsorption capacity of the system does not increase the capacity of the power system. At the same time, when the magnetic attraction force becomes weak as the thickness of the contaminated layer increases, increasing the electromagnetic force by consuming the power supply is impossible.

3.1.2 Electromagnetic Adhesion Technology

The use of permanent magnets makes the robot attached more reliably to the hull, but its disadvantage is that controlling the transition between attachment and release is difficult because the magnetic force is always present. Electromagnets can be used instead of permanent magnets to manufacture the wheels and tracks of the robot. When the track is in contact with the hull, the electromagnet can be controlled to enhance the magnetic force, and when the track is separated from the hull, the electromagnet can be controlled to weaken the magnetic force. This process will increase the maneuverability of the robot, although robots that use electromagnets consume more energy than those that use permanent magnets (Yan et al. 2019 ).

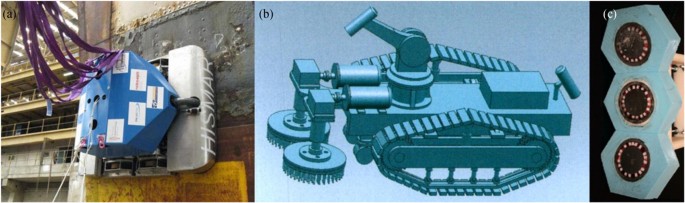

HISMAR, shown in Figure 11a , is a multifunctional robot system that is used for hull inspection and maintenance in the dock to ensure minimal vessel drag and improve propulsion efficiency. The robotic system uses a new navigation system that uses optical imaging, magnetic sensors, and the inherent structural features of the hull to construct a local map on the hull for assisting robot navigation (Balashov et al. 2011 ). Zeng and Cai ( 2012 ) designed an underwater cleaning robot that uses a combination of permanent magnet and electromagnet as the adsorption device, shown in Figure 11b . Smith and Colvin ( 2014 ) designed a magnetic fixation device to secure the cleaning robot to the hull of the vessel more securely than with the magnetic track. A variety of magnet types may be used in the fixation device, such as electromagnets that are switchable on and off or permanent magnets, which may be switchable by movement or rotation of the magnets.

Electromagnetic adhesion technology. a HISMAR ROV (Balashov et al. 2011 ). b Underwater cleaning robot (Zeng and Cai 2012 ). c Controllable adhesion system design in MIT (Nancy Stauffer, MIT Energy Initiative, http://news.mit.edu/2011/auv-series-part4-1110 )

3.2 Negative Pressure Force Adhesion

A common method of ensuring that a robot is reliably attached to the surface of a hull is to use negative pressure. This technology was first applied in wall-climbing robots for cleaning, maintenance, and inspection in the construction industries (Silva and Machado 2010 ). With the application of fluid kinematics technology, a certain negative pressure region is generated between the robot adsorption device and the working surface, and the required adhesion force is generated by the pressure difference.

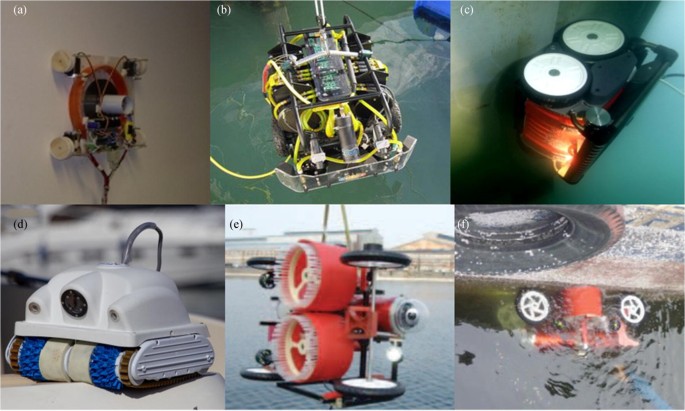

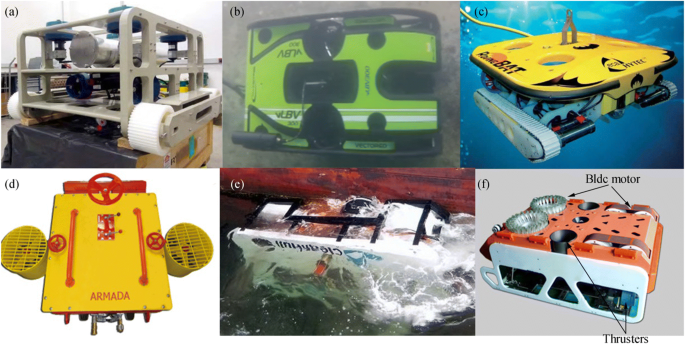

Sliding vacuum chambers is another method of generating negative pressure (Longo and Muscato 2006 ). As shown in Figure 12a , Alicia VTX is a new climbing robot that uses an intelligent active suction cup. The suction cup consists of a rigid plastic cup and a propeller driven by a DC motor (Longo and Muscato 2006 ). The underwater hull cleaning robot HullBUG, designed by SeaRobotics, is a UUV crawler targeted to perform proactive grooming of large vessel hulls and other underwater surfaces, as shown in Figure 12b (Holappa et al. 2013 ). Hullbot is a robot primarily used for yacht cleaning, as shown in Figure 12c (Souto et al. 2015 ). KeelCrab Sail One, as shown in Figure 12d , can be used for not only yacht cleaning but also hull inspections (Souto et al. 2015 ). Nassiraei et al. ( 2012 ) developed an underwater hull cleaning robot, as shown in Figure 12e and f . The size of the robot is about 1100 mm × 500 mm × 800 mm, and the weight is about 40 kg.

Robots using negative pressure adsorption technology. a Alicia VTX Robot ( http://www.robotic.diees.unict.it/robots/alicia_vtx/alicia_vtx.htm ). b SeaRobotics’ HullBUG (Ferreira et al. 2013 ). c Hulltimo Robot (HULLTIMO, https://services.crmservice.eu/raiminisite?a=FEY9pLHXWFV1XHUy5r0nDqOUKD6w3VRLkQkSahxnWjg= ). d KeelCrab Sail One (KELLCRAB, http://www.keelcrab.com/keelcrab-sail-one-drone-sottomarino/ ). e , f Underwater robot for cleaning ship hull (Nassiraei et al. 2012 )

3.3 Thrust Force Adhesion

Many underwater robots that use thrust force adhesion technology have been developed for various applications, such as the inspection of the surface of storage tanks or ships (Sattar et al. 2002 ; Osaka et al. 2010 ; Osaka and Norita 2014 ). Compared with the vacuum adsorption technology, the thrust adsorption is greatly improved and no pressure leakage problem occurs. Unlike magnetic adsorption technology, robots designed with thrust adsorption technology can be applied to almost all ship shell materials (Ferreira et al. 2013 ).

Ferreira et al. ( 2013 ) developed an underwater robot in the Federal University of ABC, which is used to survey the hull and marine structures, as shown in Figure 13a . The robot uses six thrusters to achieve 6-DOF free-swimming in the water and uses two powered tracks to make it crawl on the surface of the ship. In the crawler mode, four thrusters are used to generate propulsion and ensure that the robot is reliably absorbed on the hull. Teledyne SeaBotix, Inc., built a hull inspection ROV (vLBC ROV) to inspect ship hulls and marine structures, as shown in Figure 13b . The vLBC ROV uses the unique and patented Vortex VRAM Generator to generate an adhesion force of about 274 N to attach on the hull. The ACE Group developed ROVIN-BAT, which can move along the surface of the ship and use high-pressure water to clean the hull (Souto et al. 2015 ; Albitar et al. 2016 ). SeaRazor Twin AST 307/LT is an efficient underwater cleaning system that uses powered rotary brushes as cleaning devices, as shown in Figure 13d . CleanHull’s operations took off in 2003, and its unique method of washing hulls underwater caught attention after only 3 years of operation, as shown in Figure 13e . Daewon Mechatronics Co. developed an underwater robot that can perform bottom inspection and cleaning, as shown in Figure 13f .

Robots using thrust force adhesion technology. a HROV’s mechanical assembly (Ferreira et al. 2013 ). b vLBC ROV (Albitar et al. 2016 ) ( https://www.youtube.com/watch?v=YydCgpl6lzY ). c Roving Bat ROV. d SeaRazor SuperTwin ( https://armadahull.com/products/ast-307-searazor-supertwin/ ). e CleanHull ROV ( https://www.telen.no/nyheter/cleanhull-kjopt-av-milliardar/s/2-2.3402-1.4669853 ). f The hull cleaning robot ( http://www.daewonsys.com/eng/sub_html/sub03_03.php )

3.4 Other Adhesion Technologies

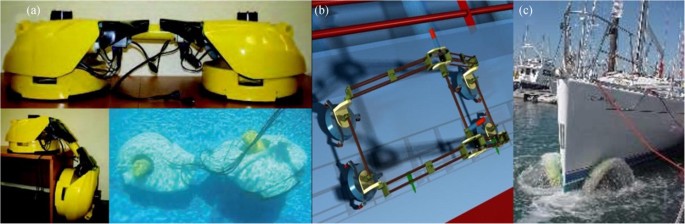

Souto et al. ( 2013 ) designed a new underwater hull cleaning robot, as shown in Figure 14a . It is mainly used to clean the hull regularly to avoid excessive growth of marine organisms that decrease the performance of the ship. This robot, which is 1690 mm long, 554 mm wide, and 340 mm high, is an underactuated and deformable robot that solves the problem of moving on different surfaces of the hull (Souto et al. 2013 , 2015 ). Albitar et al. ( 2016 ) designed a crawling robot, as shown in Figure 14b , that is mainly composed of a moving mechanism, suction cups, and cleaning devices (Albitar et al. 2013 , 2014 , 2016 ). NESSIE is an underwater hull cleaning robot that uses two circular rotating brushes, as shown in Figure 14c (Albitar et al. 2016 ).

Other adhesion technologies. a Mechanical design, motion, and real environment test of the robot (Souto et al. 2013 ). b The crawling robot (Albitar et al. 2016 ). c NESSIE robot (Albitar et al. 2016 )

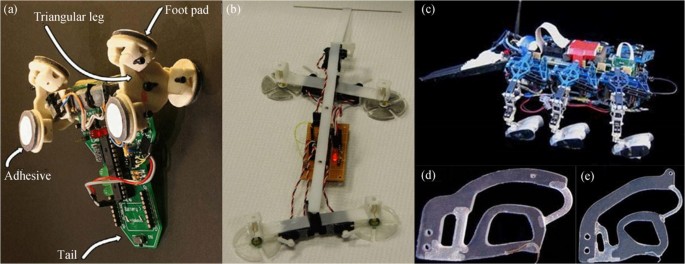

In the past decade, robot designers have gained much inspiration from climbing animals (Daltorio et al. 2005 ; Menon et al. 2004 ; Tan et al. 2018 ). Murphy et al. ( 2006 ) designed a small wall-climbing robot named Waalbot, whose feet are made of adhesive elastomer materials, allowing it to move on a smooth surface. Two rotatable legs allow Waalbot to crawl at a speed of 60 mm/s on a vertical wall and make turns at different rotational speeds. Geckobot weighs 100 g and can crawl along a glass surface with a slope of 85° (Unver et al. 2006 ). Asbeck et al. ( 2006 ) designed a six-foot walking robot called RiSE (Figure 15 ).

Biologically inspired adhesion robots. a Waalbot (Murphy et al. 2006 ). b Geckobot (Unver et al. 2006 ). c RiSE and d its toe with a large spine and e toe with a small spine (Asbeck et al. 2006 )

4 Discussion

The underwater cleaning objective of all the above-mentioned cleaning methods is to remove all visible and macroscopic biofouling on the hull. However, the removal step does not kill all the biofouling removed from the hull; a critical step is to capture the biofouling and treat it. This issue is why some countries and regions have introduced laws or regulations prohibiting foreign vessels from being cleaned in their ports or territorial seas. In the current widely used underwater cleaning system, the fragmentation, filtration, and dislodgement processes play an important role in avoiding the natural dispersal of marine organisms that are removed from the hull. Before the treatment process mentioned above, the waste has to be captured from the water to the on-ship processing device. The pipes and suction equipment used in the capture of waste and the auxiliary vessel and waste treatment equipment installed on it make the underwater robotic cleaning system complicated and difficult to operate. We recommend local heating, UV irradiation, or sterilization methods that do not use chemical biocides, which need to be further improved in the future, as an alternative to waste treatment methods. The processing equipment can be integrated into the underwater robot, making the underwater robot cleaning system more compact and efficient, which could greatly reduce the operation costs of an underwater hull cleaning system.

The optimization and combination of various technologies in the underwater cleaning robot system discussed in this review are a possible research direction for the industrialization of underwater cleaning robots. In improving underwater cleaning technology, we recommend combining the rotating brush unit with cavitation jets and integrating them into the underwater robot; this approach does not significantly increase the energy consumption of the system. For example, in designing a permanent-magnet track, an electromagnet module is embedded. When the permanent magnet is in the adsorption state, the electromagnet generates an effect of enhancing the magnetic force; in the opposite case, the electromagnet generates an effect of canceling the magnetic force. The other adsorption methods (e.g., bio-inspired adhesion technology) mentioned in this review could also be used in combination to overcome specific technical problems or produce better adsorption effects with the objective of improving the design level of cleaning robots to create more reliable industrial robot products.

Major changes in the application of artificial intelligence and multirobot cooperation in underwater cleaning robots could be expected to further lead to breakthroughs in developing next-generation robots for underwater cleaning. Therefore, robots should be given a higher level of autonomy to allow it to automatically navigate the ship hull and replan the cleaning mode. We could add more sensors and tools to enhance the inspection capabilities of the cleaning robot and use artificial intelligence algorithms to give the robots more powerful information processing and decision-making capabilities. In making the cleaning robots smarter, the indispensable prerequisite of all of these improvements is that they do not add too much to the complexity and cost of the robot system. Moreover, we would like to recommend using multirobot cooperation and enabling the robots to cooperate in fulfilling cleaning tasks. Each robot could play a role by using different cleaning techniques at different efficiencies and speeds. Such processes can inspire new underwater cleaning technologies, which hypothetically can promote the entire underwater cleaning industry in a more effective and efficient way.

5 Summary and Conclusions

This paper describes the development of ship cleaning technology over the past three decades, focusing on the classification of different underwater cleaning techniques and the comparison and analysis of different types of cleaning devices (e.g., rotary brushes, high-pressure and cavitation water jet technology, ultrasonic technology, laser cleaning technology). In addition, a survey of different technologies for the adhesion to the hull is presented, with special emphasis on the new adhesion technologies being developed. This paper surveyed the details of a series of underwater hull cleaning robots to offer solutions to problems that currently concern the ship cleaning industry. Through this overview, the following conclusions can be drawn:

The current cleaning devices are well developed, and many companies have launched serialized products according to the needs of the market. The ultrasonic and laser cleaning technologies will be more promising technologies, and their application will make the underwater robot cleaning system more compact in the future.

After being used as a platform equipping cleaning devices, unmanned underwater vehicles have greatly promoted the development of underwater cleaning technology. Should the bio-inspired adhesion technology become more cost-effective and robust in the future, it will greatly increase the robots’ adhesion power while reducing the energy consumption of the cleaning robot system when it is used to the design of robotic tracks or wheels.

The optimization and combination of various technologies in the underwater cleaning robot system discussed in this review need to be further researched in the future to increase the cleaning efficiency and decrease the required power. Major changes in the application of artificial intelligence and multirobot cooperation in underwater cleaning robots could be expected to further lead to breakthroughs in developing next-generation robots for underwater cleaning.

Adland R, Cariou P, Jia H, Wolff FC (2018) The energy efficiency effects of periodic ship hull cleaning. J Clean Prod 178:1–13. https://doi.org/10.1016/j.jclepro.2017.12.247

Article Google Scholar

Albitar H, Ananiev A, Kalaykov I (2013) New concept of in-water surface cleaning robot. 2013 IEEE International Conference on Mechatronics and Automation, Takamatsu, pp 1582–1587

Google Scholar

Albitar H, Ananiev A, Kalaykov I (2014) In-water surface cleaning robot: concept, locomotion and stability. Int J Mechatron Auto 4(2):104–115. https://doi.org/10.1504/ijma.2014.062338

Albitar H, Dandan K, Ananiev A, Kalaykov I (2016) Underwater robotics: surface cleaning technics, adhesion and locomotion systems. Int J Adv Robot Syst 13(1):7. https://doi.org/10.5772/62060

Aldrich C, Qi BC (2005) Removal of organic foulants from membranes by use of ultrasound. Water Research Commission. University of Stellenbosch, Stellenbosch WRC Report No. 1229/1/05

Asbeck AT, Kim S, McClung A, Parness A, Cutkosky MR (2006) Climbing walls with microspines. IEEE International Conference on Robotics and Automation, Orlando, pp 4315–4317

Balashov VS, Gromov BA, Ermolov IL, Roskilly AP (2011) Cleaning by means of the HISMAR autonomous robot. Russ Eng Res 31(6):589–592. https://doi.org/10.3103/s1068798x11060049

Bax N, Williamson A, Aguero M, Gonzalez E, Geeves W (2003) Marine invasive alien species: a threat to global biodiversity. Mar Policy 27(4):313–323. https://doi.org/10.1016/s0308-597x(03)00041-1

Bixler GD, Bhushan B (2012) Biofouling: lessons from nature. Philos Trans R Soc A Math Phys Eng Sci 370(1967):2381–2417. https://doi.org/10.1098/rsta.2011.0502

Caduff EA (1990) Robotic ultrasonic cleaning and spraying device for ships’ hulls. U.S. Patent No. 4890567. Washington: U.S. Patent and Trademark Office, 3–5

Chambers LD, Stokes KR, Walsh FC, Wood RJ (2006) Modern approaches to marine antifouling coatings. Surf Coat Technol 201(6):3642–3652. https://doi.org/10.1016/j.surfcoat.2007.04.001

Chen GX, Kwee TJ, Lei NR, Tan KP, Choo YS, Hong MH (2010) Underwater laser cleaning for marine and offshore applications. International Congress on Applications of Lasers & Electro-Optics, Anaheim, California, USA, pp 456-460

Chen GX, Kwee TJ, Tan KP, Choo YS, Hong MH (2012) High-power fibre laser cleaning for green shipbuilding. J Laser Micro/Nanoeng 7(3):249–253. https://doi.org/10.2961/jlmn.2012.03.0003

Chen R, Fu Q, Liu Z, Hu X, Liu M, Song R (2017) Design and experimental research of an underwater vibration suction module inspired by octopus suckers. 2017 IEEE International Conference on Robotics and Biomimetics (ROBIO), Macau, pp 1002–1007

Cioanta I, McGhin C (2017) Cleaning and grooming water submerged structures using acoustic pressure shock waves. U.S. Patent No. 9840313, Washington, DC: U.S. Patent and Trademark Office, 3–4

Courson B, Shelburne J (2001) Portable encapsulated underwater ultrasonic cleaner. U.S. Patent No. 6259653, Washington, DC: U.S. Patent and Trademark Office, 1–2

Daltorio KA, Horchler AD, Gorb S, Ritzmann RE, Quinn RD (2005) A small wall-walking robot with compliant, adhesive feet. 2005 IEEE International Conference on Intelligent Robots and Systems, Edmonton, pp 3648–3653

Davidson IC, McCann LD, Sytsma MD, Ruiz GM (2008) Interrupting a multi-species bioinvasion vector: the efficacy of in-water cleaning for removing biofouling on obsolete vessels. Mar Pollut Bull 56(9):1538–1544. https://doi.org/10.1016/j.marpolbul.2008.05.024

Drake JM, Lodge DM (2007) Hull fouling is a risk factor for intercontinental species exchange in aquatic ecosystems. Aquat Invasions 2(2):121–131. https://doi.org/10.3391/ai.2007.2.2.7

Erneland MB (2014) Ultrasonic cleaning of marine geophysical equipment. U.S. Patent Application No. 13/629,412, Washington, DC: U.S. Patent and Trademark Office, 1–3

Ferreira CZ, Conte GYC, Avila JPJ, Pereira RC, Ribeiro TMC (2013) Underwater robotic vehicle for ship hull inspection: control system architecture. 22nd International Congress of Mechanical Engineering, Ribeirão Preto, Brazil, pp 1231–1241

Floerl O, Peacock L, Seaward K, Inglis G (2010) Review of biosecurity and contaminant risks associated with in-water cleaning. The Department of Agriculture, Fisheries and Forestry, Sydney, Australia The National Institute of Water and Atmospheric Research Report

Fowler MP (1987) Optical cleaning system for removing matter from underwater surfaces. U.S. Patent No. 4689523, Washington, DC: U.S. Patent and Trademark Office, 2–3

Godwin LS (2003) Hull fouling of maritime vessels as a pathway for marine species invasions to the Hawaiian Islands. Biofouling 19(S1):123–131. https://doi.org/10.1080/0892701031000061750

Holappa KW, Darling DT, Hertel III WM (2013) Robotic submersible cleaning system. U.S. Patent No. 8506719, Washington, DC: U.S. Patent and Trademark Office, 4–5

Hopkins G, Forrest B, Coutts A (2009) Determining the efficacy of incursion response tools: rotating brush technology (coupled with suction capability). MAF Biosecurity, Wellington, New Zealand MAF Biosecurity Technical Report, Research Project ZBS2005-21

Hua J, Chiu YS, Tsai CY (2018) En-route operated hydroblasting system for counteracting biofouling on ship hull. Ocean Eng 152:249–256. https://doi.org/10.1016/j.oceaneng.2018.01.050

Huang Z, Chen Y, Yang C, Fan J, Jiang P (2017) Teleoperate system of underwater cleaning robot based on HUD. 11th Asian Control Conference (ASCC), Gold Coast, Australia, pp 2675–2679

Kalumuck KM, Chahine GL, Frederick GS, Aley PD (1997) Development of a DYNAJET cavitating water jet cleaning tool for underwater marine fouling removal. 9th American Waterjet Conference, Dearborn, Michigan, USA, pp 541–554

Kostenko VV, Bykanova AY, Tolstonogov AY (2019) Underwater robotics complex for inspection and laser cleaning of ships from biofouling. IOP Conf Ser: Earth Environ Sci 272(2):1–7

Lakretz A, Ron EZ, Mamane H (2009) Biofouling control in water by various UVC wavelengths and doses. Biofouling 26(3):257–267. https://doi.org/10.1080/08927010903484154

Lee MH, Park YD, Park HG, Park WC, Hong S, Lee KS, Chun HH (2012) Hydrodynamic design of an underwater hull cleaning robot and its evaluation. Int J Naval Arch Ocean Eng 4(4):335–352. https://doi.org/10.3744/jnaoe.2012.4.4.335

Legg M, Yücel MK, De Carellan IG, Kappatos V, Selcuk C, Gan TH (2015) Acoustic methods for biofouling control: a review. Ocean Eng 103:237–247. https://doi.org/10.1016/j.oceaneng.2015.04.070

Longo D, Muscato G (2006) The Alicia/sup 3/climbing robot: a three-module robot for automatic wall inspection. IEEE Robot Autom Mag 13(1):42–50. https://doi.org/10.1109/mra.2006.1598052

Mazue G, Viennet R, Hihn JY, Carpentier L, Devidal P, Albaïna I (2011) Large-scale ultrasonic cleaning system: design of a multi-transducer device for boat cleaning (20 kHz). Ultrason Sonochem 18(4):895–900. https://doi.org/10.1016/j.ultsonch.2010.11.021

Menon C, Murphy M, Sitti M (2004) Gecko inspired surface climbing robots. 2004 IEEE International Conference on Robotics and Biomimetics, Shenyang, China, pp 431–436

Morrisey DJ, Woods C (2015) In-water cleaning technologies: review of information. Publications Logistics Office, Ministry for Primary Industries, Wellington, pp 20–25

Murphy MP, Tso W, Tanzini M, Sitti M (2006) Waalbot: an agile small-scale wall climbing robot utilizing pressure sensitive adhesives. 2006 IEEE/RSJ International Conference on Intelligent Robots and Systems, Beijing, pp 3411–3416

Nassiraei AAF, Sonoda T, Ishii K (2012) Development of ship hull cleaning underwater robot. 2012 Fifth International Conference on Emerging Trends in Engineering and Technology, Himeji, pp 157–162

Oliveira D (2017) The enemy below-adhesion and friction of ship hull fouling. Master thesis, Chalmers University of Technology, Gothenburg, Sweden, 56–67

Osaka T, Norita J (2014) Submersible cleaning robot. U.S. Patent No. 8757181, Washington, DC: U.S. Patent and Trademark Office, 2–4

Osaka T, Yakushiji H, Hirata D (2010) Underwater cleaning robot and auxiliary cleaning work machine. U.S. Patent No. 12/735,720, Washington, DC:vU.S. Patent and Trademark Office, 3–4

Pivovarov A (2009) Cleaning of submerged surfaces by discharge of pressurized cavitating fluids. U.S. Patent No. 7494073, Washington, DC: U.S. Patent and Trademark Office, 4–5

Ross B, Bares J, Fromme C (2003) A semi-autonomous robot for stripping paint from large vessels. Int J Robot Res 22(7–8):617–626. https://doi.org/10.1177/02783649030227010

Satpathy KK, Mohanty AK, Sahu G, Biswas S, Prasad MVR, Slvanayagam M (2010) Biofouling and its control in seawater cooled power plant cooling water system-a review. In: Nuclear Power, pp 191–242. https://doi.org/10.5772/9912

Chapter Google Scholar

Sattar T P, Zhao Z, Feng J, Bridge B, Mondal S, Chen S (2002) Internal in-service inspection of the floor and walls of oil, petroleum, and chemical storage tanks with a mobile robot. 5th International Conference on Climbing and Walking Robots and the Support Technologies for Mobile Machines, Paris, France, pp 947-954

Silva MF, Machado JT (2010) A survey of technologies and applications for climbing robots locomotion and adhesion. Climb Walk Robots:1–22. https://doi.org/10.5772/8826

Smith FM, Colvin G (2014) Magnetic track. U.S. Patent Application No. 2014/0077.587, Washington, DC: U.S. Patent and Trademark Office, 6–7

Song WD, Hong MH, Lukyanchuk B, Chong TC (2004) Laser-induced cavitation bubbles for cleaning of solid surfaces. J Appl Phys 95(6):2952–2956. https://doi.org/10.1063/1.1650531

Souto D, Faiña A, López-Peña F, Duro RJ (2013) Lappa: a new type of robot for underwater non-magnetic and complex hull cleaning. IEEE International Conference on Robotics and Automation, Karlsruhe, pp 3409–3414

Souto D, Faiña A, López-Peña F, Duro RJ (2015) Morphologically intelligent underactuated robot for underwater hull cleaning. 2015 IEEE 8th International Conference on Intelligent Data Acquisition and Advanced Computing Systems: Technology and Applications, Warsaw, Poland, pp 879–886

Tan W, Zhang C, Liu L (2018) An introduction to biomimetic underwater adhesion system. 13th World Congress on Intelligent Control and Automation (WCICA), Changsha, China, pp 479–483

Tribou M, Swain G (2010) The use of proactive in-water grooming to improve the performance of ship hull antifouling coatings. Biofouling 26(1):47–56. https://doi.org/10.1080/08927010903290973

Unver O, Uneri A, Aydemir A, Sitti M (2006) Geckobot: a gecko inspired climbing robot using elastomer adhesives. Proceedings 2006 IEEE International Conference on Robotics and Automation, Orlando, pp 2329–2335

Veiko VP, Shakhno EA (2002) Physical mechanisms of laser cleaning. In: Boris L (ed) Laser cleaning. World Scientific, Singapore, pp 311–340

Vodenicharov S, Bratanov D, Michailova R, Stoychev K, Najdenov V (2017) Underwater hull observation system ARMUS. 15th International Scientific Congress on Machines, Technologies, Materials, Borovets, Bulgaria, pp 319–322

Wotton DM, O'Brien C, Stuart MD, Fergus DJ (2004) Eradication success down under: heat treatment of a sunken trawler to kill the invasive seaweed Undaria pinnatifida. Mar Pollut Bull 49(9–10):844–849. https://doi.org/10.1016/j.marpolbul.2004.05.001

Yan H, Yin Q, Peng J, Bai B (2019) Multi-functional tugboat for monitoring and cleaning bottom fouling. IOP Conf Ser: Earth Environ Sci 237(2):1–6. https://doi.org/10.1088/1755-1315/237/2/022045

Yi Z, Gong Y, Wang Z, Wang X (2009) Development of a wall climbing robot for ship rust removal. 2009 International Conference on Mechatronics and Automation, Changchun, pp 4610–4615

Yuan FC, Guo LB, Meng QX, Liu FQ (2004) The design of underwater hull-cleaning robot. J Mar Sci Appl 3(1):41–45. https://doi.org/10.1007/bf02918646

Zabin C, Davidson I, Ruiz G (2017) In-water vessel cleaning: current and emerging technologies, associated risks, and management options for Hawaii. Smithsonian Environmental Research Center, Hawaii State, USA Final report to the Hawaii State Department of Land and Natural Resources

Zeng C, Cai ZX (2012) The study of hull cleaning remote-control machine. Robot Tech Appl 29(1):14–17. https://doi.org/10.3969/j.issn.1004-6437.2012.01.005

Download references

Supported by the General Program of the National Natural Science Foundation of China under Grant No. 51879157, the “Construction of a Leading Innovation Team” project by the Hangzhou Municipal Government, and the Startup Funding of Newjoined PI of Westlake University under Grant No. 041030150118.

Author information

Authors and affiliations.

Deep Sea Technology Research Center, School of Engineering, Westlake University, Hangzhou, 310024, China

Changhui Song & Weicheng Cui

Shanghai Engineering Research Center of Hadal Science and Technology, Shanghai Ocean University, Shanghai, 201306, China

Weicheng Cui

You can also search for this author in PubMed Google Scholar

Corresponding author

Correspondence to Weicheng Cui .

Additional information

• The development status of underwater cleaning robot is introduced.

• The development trend of underwater cleaning robot technology is summarized.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/ .

Reprints and permissions

About this article

Song, C., Cui, W. Review of Underwater Ship Hull Cleaning Technologies. J. Marine. Sci. Appl. 19 , 415–429 (2020). https://doi.org/10.1007/s11804-020-00157-z

Download citation

Received : 11 November 2019

Accepted : 12 May 2020

Published : 13 October 2020

Issue Date : September 2020

DOI : https://doi.org/10.1007/s11804-020-00157-z

Share this article

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

- Dry-dock cleaning

- Underwater ship cleaning

- Adhesion technology

- Cleaning robot

- Find a journal

- Publish with us

- Track your research

- International

Israel-Hamas war

Northeast earthquake

Jobs report

March 27, 2024 - Baltimore Key Bridge collapse

By Kathleen Magramo , Antoinette Radford, Alisha Ebrahimji , Maureen Chowdhury , Elise Hammond , Tori B. Powell and Aditi Sangal , CNN

Our live coverage of the Baltimore bridge collapse has moved here .

Here's what you should know about the Key Bridge collapse

From CNN staff

Officials recovered the bodies of two construction workers who were on Baltimore's Francis Scott Key Bridge when it collapsed early Tuesday morning after a 984-foot-long cargo ship collided into a pillar.

Maryland Gov. Wes Moore called the collapse Wednesday " a global crisis ."

"The national economy and the world's economy depends on the Port of Baltimore. The port handles more cars and more farm equipment than any other port in the country," Moore said.

Here's what you should know:

- The victims: The six people who are presumed dead were from Mexico Guatemala, El Salvador and Honduras, according to Col. Roland L. Butler Jr, the superintendent of Maryland State Police. Two bodies were recovered and have been identified as Alejandro Hernandez Fuentes from Mexico and Dorlian Ronial Castillo Cabrera from Guatemala. The two workers were filling potholes on the bridge and were later found trapped in a red pickup truck in about 25 feet of water, Butler said. The FBI is handling notifying the victims' families, Butler said.

- Recovery efforts: Authorities are pausing search efforts for the four other workers who are presumed dead, because additional vehicles are encased in concrete and other debris, making it unsafe for divers, Butler said. Once salvage operations clear the debris, divers will search for more remains, he said.

- The investigation: The National Transportation Safety Board is leading the investigation into the fatal incident, according to the agency's chair Jennifer Homendy. During a Wednesday news conference, Homendy said there were 21 crew members and two pilots on board the Dali cargo ship when it crashed into the bridge. She also said a senior NTSB hazmat investigator identified 56 containers of hazardous material, and that some containers are in the water. The agency received six hours of voyage data from the ship and the investigation could take 12 to 24 months to complete, Homendy said. She emphasized that NTSB will not analyze information collected or provide conclusions while on scene of the collapse.

- Looking forward: Department of Transportation Secretary Pete Buttigieg said rebuilding the bridge will not be "quick or easy" but that it will get done. He said there are four main focus points ahead: reopening the port, dealing with supply chain issues until its reopening, rebuilding the bridge and dealing with traffic issues until the bridge is rebuilt. Biden pledged the full support of the federal government in the response and recovery efforts. His administration has already conveyed a sense of urgency to open up federal funding to remove debris and ultimately rebuild the bridge. Maryland has submitted a request to the Biden administration for emergency relief funds "to assist in our work going forward," Moore said Wednesday.

It's almost impossible to place people on the bow of ship due to the unstable structure, fire official says

From CNN's Sarah Engel

Baltimore City Fire Chief James Wallace said Wednesday that the cargo ship's bridge structure and containers at the bow remain unstable.

"It's going to be very difficult, if not impossible, and very dangerous, to place people on the bow of that boat right now," Wallace told CNN's Kaitlan Collins.

"Naturally, we're still very cognizant of the fact that there are hazardous materials on board the vessel itself," Wallace said, alluding to the National Transportation Safety Board saying earlier that 56 containers were carrying hazardous materials.

Wallace said his team is relying heavily on aerial recognizance, including drones. "That's the only way we're able to see in," he said.

He added that the aerial surveillance has "been able to really assure us right now we have no [chemical] reactions on board."

"It's just utter devastation," NTSB chief says of the bridge collapse site

From CNN's Aditi Sangal

Jennifer Homendy, chair of the National Transportation Safety Board, called the site of the Key Bridge collapse "devastating."

"It's pretty devastating, certainly, seeing not just what's going on with the cargo containers, but just looking at what was a bridge span — three bridge spans that is pretty much gone. It's just utter devastation," she said at Wednesday evening's news briefing.

She added that she is thinking of families who lost loved ones and those who are waiting to reunite with their lived ones.

NTSB interviewed the Dali's captain and some other crew members today, agency chief says

The National Transportation Safety Board has interviewed the ship's captain, his mate, the chief engineer and one other engineer today, according to Chair Jennifer Homendy.

The two pilots on board the Dali at the time of collision will be interviewed tomorrow, she added.

Cargo ship's voyage data recorder is basic when compared to an airplane's, NTSB chair says

From CNN's Tori B. Powell

The voyage data recorder on the cargo ship Dali was a "newer model" but is considered basic when compared to that on an airplane, according to National Transportation Safety Board Chair Jennifer Homendy.

"But it is very basic compared to say, a flight data recorder, where we would have 1,000 parameters," she said at a news conference on Wednesday.

The NTSB chief investigator Marcel Muise added:

"It's not a ship-wide system recorder, so most of the sensors that are being recorded are from the bridge. So things like GPS, the audio, rudder feedback, rudder commands are recorded on there. But not engineering, the temperature of each cylinder, power distribution sensors."

There were no tug boats with Dali at the time of the collision. That's normal, NTSB chief says

There were no tugs with Dali when the cargo vessel collided with Baltimore's Key Bridge, which is normal protocol, according to National Transportation Safety Board Chair Jennifer Homendy.

Remember: At 01:26:39 on Tuesday, Dali's pilot made a general very high frequency (VHF) radio call for tugs in the vicinity to assist, the NTSB investigator Marcel Muise had said.

"The tugs help the vessel leave the dock, leave the port and get into the main ship channel. And then they leave. Once it's on its way, it's a straight shot through the channel. So there are no tugs with the vessel at the time. So they were calling for tugs," she said.

NTSB chair says she saw some containers that were carrying hazardous materials in the water

National Transportation Safety Board Chair Jennifer Homendy said she did see some of the 56 containers that were carrying hazardous materials in the water.

When asked how many

When asked how many containers of hazardous materials were in the water, Homendy said:

"I did see some containers in the water, and some breached significantly on the vessel itself," she said. "I don't have an exact number, but it's something that we can provide in an update."

Homendy said that a preliminary report should be out in two to four weeks.

This post has been updated with more quotes from Homendy.

Bridge did not have any redundancy, unlike the preferred method for building bridges today, NTSB chair says

Baltimore's Key Bridge did not have any redundancy, which is included in the preferred method of building bridges in the present day, according to National Transportation Safety Board Chair Jennifer Homendy.

"The bridge is a fracture critical," she explained. "What that means is if a member fails that would likely cause a portion of, or the entire bridge, to collapse, there's no redundancy. The preferred method for building bridges today is that there is redundancy built in, whether that's transmitting loads to another member or some sort of structural redundancy. This bridge did not have redundancy," Homendy said.

There are 17,468 fracture critical bridges in the United States out of 615,000 bridges total, she said, citing the Federal Highway Administration.

Please enable JavaScript for a better experience.

Advertisement

How the Key Bridge Collapsed in Baltimore: Maps and Photos

By Weiyi Cai , Agnes Chang , Lauren Leatherby , Lazaro Gamio , Leanne Abraham and Scott Reinhard

On Tuesday, a major bridge in Baltimore collapsed into the water seconds after it was struck by a cargo ship, sending vehicles on the bridge into the river below. The ship lost power and issued a mayday call shortly before it hit the bridge.

The ship, a 948-foot-long cargo vessel called Dali, was about a half hour into its journey toward Colombo, Sri Lanka, when it hit a main pillar of the bridge. All crew members are safe, according to the ship’s owners.

Follow our live coverage .

A mayday call from the ship gave officials enough time to stop traffic at both ends of the bridge. The waters where the bridge collapsed are about 50 feet deep. By Tuesday morning, six construction workers who had been fixing potholes on the bridge remained missing as divers and other emergency workers on boats and helicopters continued to search for them. Two others had been rescued, and one was in the hospital.

Francis Scott

Patapsco River

The ship left the Port

of Baltimore around

1 a.m. on Tuesday.

Where impact occurred

Direction of the ship

The ship hit the

bridge at 1:28 a.m.

The ship hit the bridge at 1:28 a.m.

Where impact

Source: Spire Global

The New York Times; satellite image by Google Earth

The lights of the ship flickered on and off as it lost power in the minutes before the ship changed bearing and hit the bridge.

Ship approached from

the Port of Baltimore

Road repair crews

Ship changed heading

as it neared pillar

Ship hit pillar

Southern and central spans

of bridge began to collapse within

seconds of impact

Northern span began to

collapse seconds later

Within 30 seconds of impact,

the central part of bridge had

entirely collapsed.

Source: StreamTime Live via YouTube

Timestamps are from StreamTime Live video.

The New York Times

The Francis Scott Key Bridge was opened in 1977 and carried more than 12.4 million vehicles last year. The bridge was one of the three major ways to cross the Patapsco River and formed part of Baltimore’s beltway.

The Port of Baltimore is a major trade hub that handled a record amount of foreign cargo last year. It is an especially important destination — the nation’s largest by volume last year — for deliveries of cars and light trucks.

Ship impact

To Chesapeake Bay

Sources: Maryland Port Administration, OpenStreetMap, MarineTraffic

Note: Ship positions are as of 2:46 p.m. Eastern time.

Overall, Baltimore was the 17th biggest port in the United States in 2021, ranked by total tons, according to the Bureau of Transportation Statistics. The bridge collapse brought marine traffic there to a standstill, with seven cargo or tanker ships stranded in the harbor as of Tuesday afternoon.

Gov. Wes Moore declared a state of emergency for Maryland and said that his office was in close communication with Pete Buttigieg, the U.S. transportation secretary. The White House issued a statement saying that President Biden had been briefed on the collapse.

Erin Schaff/The New York Times

- Share full article

IMAGES

VIDEO

COMMENTS

Our water systems are becoming increasingly polluted, which poses a serious threat to both human and aquatic life. The hazardous waste present in the water can be fatal for aquatic animals that consume it. Furthermore, humans are also vulnerable to the consequences of this issue, as the contaminated water is employed for drinking and irrigation purposes. The utilization of such water in ...

trash from the water bodies. The Water cleaning boat Project is an endeavour to clean water bodies with an ambitious mission: to achieve cleaner water-bodies that are free from suspended solids; to reduce human intervention and human labour. This project gives a solution of automated river cleaning with the help of a tread mill arrangement.

This paper utilizes a water surface cleaning robot powered by solar energy, incorporating computer vision and mobile applications to monitor and alert authorities about pollution sources in Indian water bodies. 4 Design and Analysis of River Water Cleaning Machine Madhavi N.Wagh, Kashinath Munde Research in this paper focuses

The solution proposed in this paper aims to reduce water pollution and the deaths of aquatic animals caused due to marine debris. This robot can currently be used in standing water bodies such as lakes, ponds among others. Future alterations can be made to the robot to help in cleaning of flowing water bodies as well. 2. Literature review

These may typically be formed as a catamaran-type hull, i.e., a pair of pontoons or sponsors, or as a monohull, with paddle wheel or screw driver propulsion, and an operator station. In one typical trash skimmer design, one or more hydraulically powered open mesh conveyors are positioned between the pontoons of a catamaran-type twin-hull vessel ...

Our work aims to create a garbage gathering object to monitor the lakes and ponds and also measure the condition of water by measuring several parameters. In addition, it helps to understand the water pollution using data analysis. The main feature of this project is to collect of floating objects from the surface of the water into a trash ...

Conference Paper. May 2021. Sophiya Susan S. Ojaswini S. View. PDF | On Jul 20, 2020, Siddhanna Janai published Swachh Hasth-A Water Cleaning Robot | Find, read and cite all the research you need ...

This paper aims to introduce a concept of an ocean/water body cleaning robot that attempts to classify the wastes using a camera with a custom machine learning model and segregate accordingly ...

TLDR. This work aims to build a solar-powered boat with maximum efficiency, to inculcate a cleanup system to collect the trash on the water surface using a conveyor belt mechanism within the boat and to develop a user-friendly website for the consumer in order to provide them with the necessary energy details. Expand.

Related work. The solar-powered water-cleaning boat shown above is entirely powered by solar energy. The PVC is used to collect the sun energy (Photo voltaic cell). The PVC has a rating of 12V and 7.3AH, and the energy passes through the CCU (charge control unit). A diode is connected between PVC and CCU, allowing power to flow exclusively in ...

also Government of India has taken charge to clean river and pond due to increasing water pollution, and so that they invest huge capital for many river cleaning project like 'Namami Ganga', 'Narmada bachao' and also developed many project in various cities like Prayagraj, Varanasi etc. 2. OBJECTIVES To design a water cleaning model.

Kandivali, Mumbai 400101, India. Abstract - This project focuses more on "Remote. Controlled Unmanned River Cleaning Bot". In India. water pollution is increasing day by day so this is. often ...

IJCRT2106229 International Journal of Creative Research Thoughts (IJCRT) www.ijcrt.org b790. 1.1. Problem Statement. In the absence of garbage disposal facilities, the practice of dumping garbage into nearby water bodies has become quite common in recent years and has posed long-term negative impacts both on biodiversity of the area and as well ...

cleaning rubbish floating on the water surface. They developed a pontoon-shaped hull that fulfills all the hydrostatic and structural criteria of the boat. The hull can bear maximum trash of up to 16 kg. Siddhanna et al [7] proposed a robotic arm that can detect, pick, and place garbage from water bodies and thereby clean the water bodies.

fabricated on the basis of literature and research on different journals and paper relevantly available and fabricated in accordance so it can provide flexibility in operation. This project "River Cleaning Ro-boat" is designed with the hope that it is very much economical and helpful to river and Pond cleaning.

A new concept of flexible crawling mechanism in the design of industrial in-water cleaning robot, which enables the scanning and cleaning process performed by water jets, while keeping stable robot position on the surface by its capacity to bear and compensate the jet reactions. Expand. 13. 1 Excerpt.

1. A Water Surface Cle aning Robot. E Rahmawati *1, I Sucahyo, A Asnawi, M Faris, M A Taqwim, D Mahendra. 1 Physics Department, Universitas Negeri Surabaya, Indonesia. * e-mail: endahrahmawati ...

A new concept of flexible crawling mechanism in the design of industrial in-water cleaning robot, which enables the scanning and cleaning process performed by water jets, while keeping stable robot position on the surface by its capacity to bear and compensate the jet reactions. Expand. 13. 1 Excerpt.